Glass Systems

ABOUT COLCOM

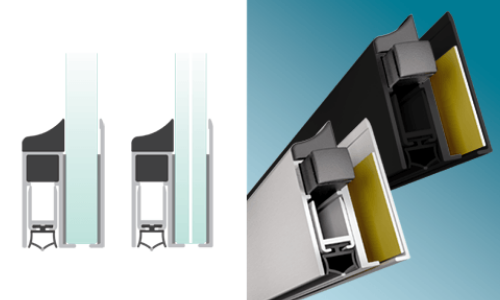

Colcom’s product range includes shower enclosures, interior and exterior doors, partitions, sliders, handles and locks.

Colcom group recently increased its product range by acquiring the French company Sadev, which specializes with studying, designing, developing and production of external fixing systems, structural façades and balustrades.

Sadev’s engineers and planning department are able to develop custom articles for big projects.

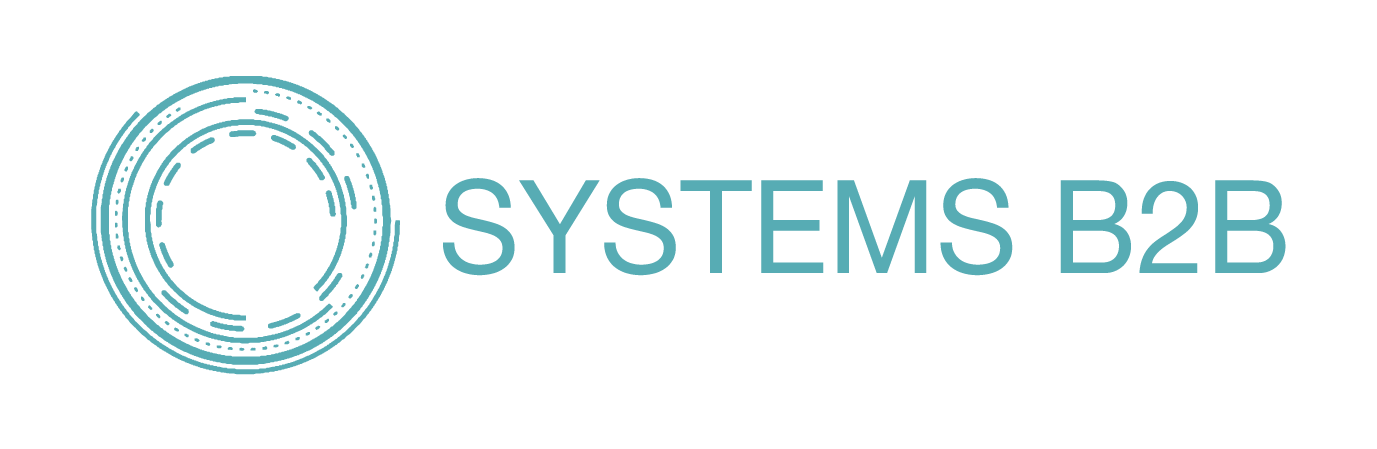

The hydraulic concept is Colcom Group prominent element of R&D that was developed and patented as evolution and synthesis of the automatic-mechanical hinges and the traditional hydraulic door closers already on the market. This can be found in hinges for internal and external doors, and shower enclosures. Thanks to the continuous effort in developing innovative products, Colcom Group has established itself in the global marketplace as a real choice brand within the construction and interior design industry.

The catalog is thus a result of Italian design and style, technical expertise acquired over the years and a remarkable feeling of grasping the marketplace needs and anticipate the trends. Galvacom does high-quality galvanic treatments and PVD, on brass and aluminum. Chrome plating on aluminum is its strength, with a continuous improvement year after year.

The French company Sadev extends Colcom’s product range by adding a whole series of external applications: fixing systems, structural façades and balustrades. A new sales and distribution network, made up by a network of general contractors and architect ateliers. The entire production process (design, machining and finishing) and distribution in the global market is fully held within Colcom Group among the production, design, support and distribution departments. This allows the Group to put in place the best solution in response to the specific marketplace demands.

Colcom was established in 1961. From a small company that was only working on behalf of a third party, in a short time, Colcom transformed its business by producing glass fittings, hinges, and door closers.

In 2003 Colcom inaugurated the new headquarters in Nave, Italy and the following year sees the establishment of Minusco Holding, which distributes Colcom products in Italy and abroad. 2007 is a further milestone, with the birth of Biloba and Triloba – patented internationally by Colcom – as a new concept of door closer hinges for the installation of glass doors.

2013 marks the birth of Colcom Group where Colcom becomes the main brand within the Group. In 2014 the company was acquired by Wise SGR, a private equity firm that, along with Colcom Group management team, started a development process with the goal of giving a strong sales push and a wider penetration worldwide.

In 2017 Colcom Group acquires the French company Sadev, which specializes with studying, designing, developing and production of external glass fixing systems, structural façades and balustrades, increasing thus the supplying range.

Colcom Group was acquired by SIMONSWERK GmbH in March 2019.SIMONSWERK Business is complementary to Colcom Group and Sadev ones. The cooperation will allow the group to furtherly develop export sales, making a strong leadership in the high-end hinges for wooden and glass door hinges even stronger.

The goal of the R&D department is to design new products and improve existing ones to meet the demands of the glass industry.

The staff, constantly updated on new softwares and technologies, is able to:

– Create new projects and study new products

– Submit realistic projects to customers, thanks to latest generation CAD CAM, before the creation of the prototype

– Realize prototypes (now also with real-time 3D printer)

– Improve production efficiency of the mechanical equipment

– Assist the designers of OEM customers in the design of specific customized solutions

Thanks to this department, Colcom Group is able to make products with technologically advanced mechanisms, hardly obtainable by those without the same expertise, and face competition particularly strong in this area.

The production process is preceded by study and design carried out by the internal technicians who, thanks to the latest generation of CAD CAM, execute drawings of the parts. They also check the structural compliance of accessories and the real-time realization of prototypes with 3D printer.

We may divide the production process into several stages:

performed by CNC machines allowing a very high level of customization. This quality production milestone has been reached through significant investments in technologies and qualified professional resources. This helps making the set-up times faster, starting combined processing methods and simplifying the optimal flow of components.

the products are roughed with emery and then finished on the surface by selected external suppliers. Robotic machines work on these functions, as they are able to ensure a constant uniformity of finish requirements. At the same time, an extra test on quality checks the correct preparation of the semi-finished product.

The surface finish treatments are handled by Galvacom, a company within the Group. Galvacom galvanic treatments are made on brass, aluminum, and PVD. Aluminum chrome plating is Colcom’s strong point.

The success of it depends on various parameters and requirements that Galvacom is able to satisfy in all working phases thanks to the expertise acquired over years of activity and continuous improvement. The process is fully automated and the cycles are controlled by a software.

Galvacom galvanic surface treatments strong points:

– Corrosion resistance

– Coating thickness

– Deposit adherence

– Abrasion resistance

– Lab testing frequency

The surface finish treatments are handled by Galvacom, a company within the Group. Galvacom galvanic treatments are made on brass, aluminum and PVD. Aluminum chrome plating is Colcom’s strong point. The success of it depends on various parameters and requirements that Galvacom is able to satisfy in all working phases thanks to the expertise acquired over years of activity and continuous improvement. The process is fully automated and the cycles are controlled by a software.

Galvacom galvanic surface treatments strong points:

– Corrosion resistance

– Coating thickness

– Deposit adherence

– Abrasion resistance

– Lab testing frequency

The galvanic facilities used by Galvacom meet different production needs and offer a complete service in the treatment of metal surfaces:

– Nickel plating treatment

– Chrome plating treatment

– Physical vapor deposition (PVD) treatment, which gives a wide range of color shades and excellent resistance to abrasion. Noble raw materials are used to give the components the desired color. Galvacom currently provides two colors: imitation of satin stainless steel and polished gold.

– Nickel plating and chrome plating, they can be made in different polished versions, the matt version is also known as “pearl”.

Galvacom guarantees high-quality chrome plating treatments in dealing with companies that need small/medium quantities with products obtained from rods or die-casting aluminum.